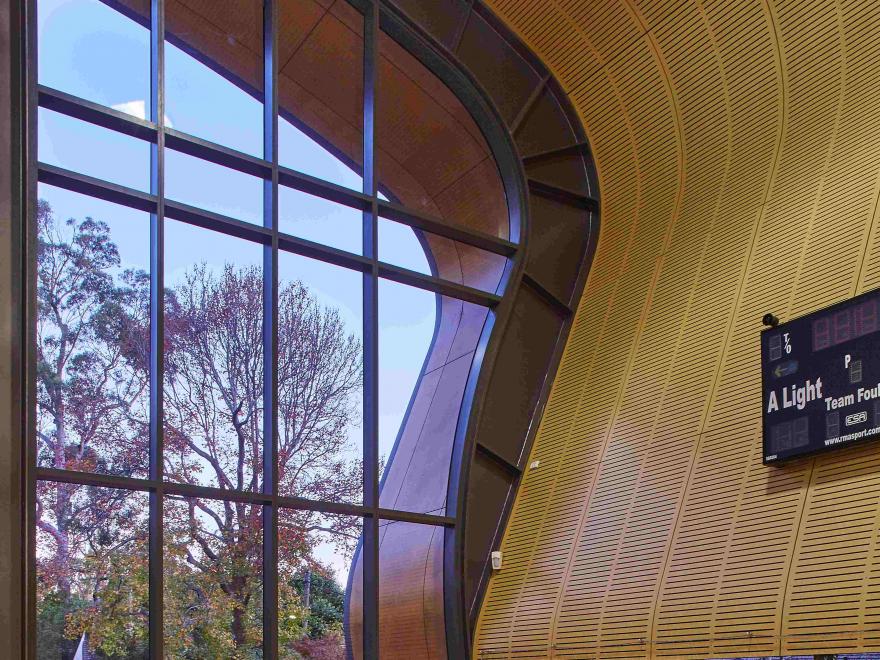

The major challenge for Prime was the fabrication of the curved steel rafters. Due to the varying radius of the architect’s design, the rafters were individually fabricated from 32mm plate for the flanges and 16m plate for the webs. The webs were cut to the profile and the flanges curved with traditional methods and fixed to the web plate with a continuous butt weld, the result being a cured universal beam.

Another feature of the rafters is they were designed not to have any visible fixing. This required all the purlins, bracing and struts to be in the same plane above the top flange. To achieve this, a lot of non-conventional connections were used and a high level of coordination was required to incorporate all the recessed services above ceiling level.

Erection of the rafters required a complex system of propping and bracing to allow the curved sections of the rafters to be joined to make one suspended member spanning from the base plate, the only other permanent fixing at the tapered end of the rafter.

The fabrication details and the difficulties overcome in erection makes this a worthy winner.

Category

Construction (Commercial) » Best Use of Structural Steel

Year

2015

Company

Prime Constructions Pty Ltd

Project

Abbotsleigh Sports Precinct

Suburb

Wahroonga

Prize

Winner